We have many years of experience with fire protection for our hall structures. Fires occurring in large steel halls are not frequent, but they happen and while this is far from a happy event for the hall’s owner, lessons learned offer us valuable information on the behaviour of steel hall structures under extreme fire conditions.

The flexibility of the LLENTAB system allows for tailoring the structure to the client’s requirements. The structures of buildings without internal supports can have a span of up to 100m with no limits for the length of the structure. The modules of the structure are precisely adapted to the internal design of the building, with modules used on a standard basis ranging from 3,600 to 9,000mm with module increments of 300mm. LLENTAB halls can have flat, pent or gabled roofs with incline ranging from 2 to 21 degrees. The internal incline can range from zero (horizontal) to parallel with the external roof incline. Halls can use internal pillars or multiple naves. Fire protection plays an important role in all such applications.

LLENTAB halls’ fire protection systems.

Our halls feature a fire protection system based on twenty years of experience in the assembly of steel halls for various purposes in the Czech Republic.

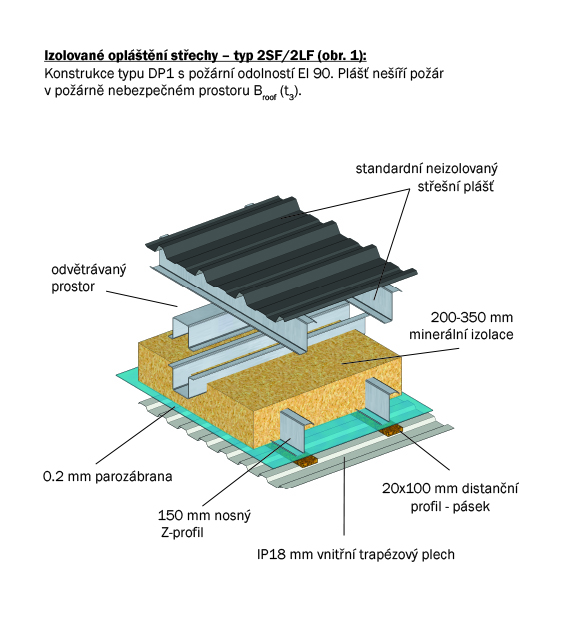

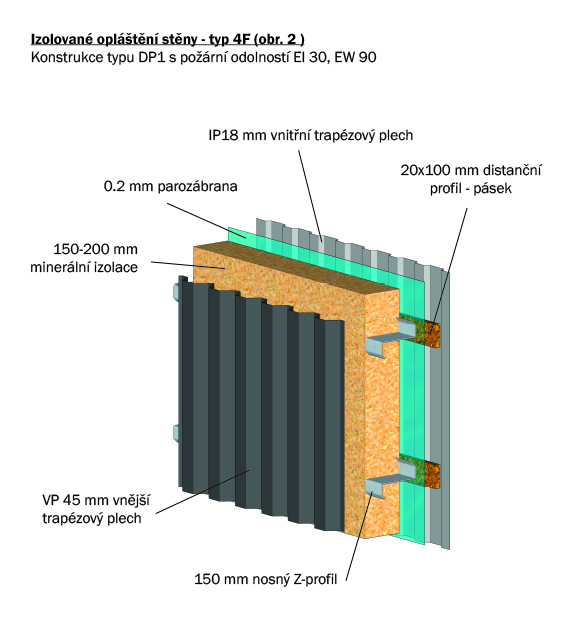

The LLENTAB 2LF soffit with fire resistance rating of EI 90 DP1 is a unique design. The 2LF installs below the roof supporting structure to provide fire resistance of all steel structures above the soffit plane. The standard structure involves 200mm of blown mineral wool insulation that perfectly fills all nooks and crannies. At the same time, the 2LF cuts heating costs by reducing the heated volume and allowing an increase in the thickness of the thermal insulation with minimum investments (see Fig. 1). A proprietary design, the LLENTAB type 4F/4FI composite wall casing has fire resistance ratings of EW 90 DP1 and EI 30 DP1. The thermal insulation is basalt wool in boards with a minimum thickness of 150mm (see Fig. 2).

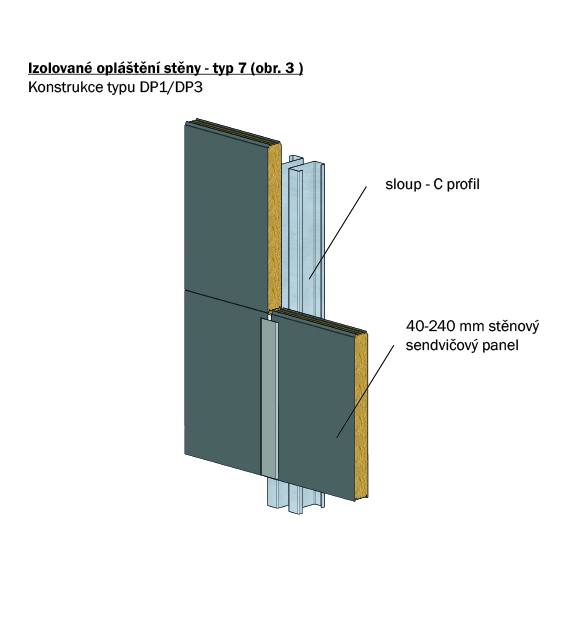

The system is complemented by LLENTAB type 7 sandwich wall panels with core of basalt thermal insulation. The sandwich panels have fire resistance ratings of EI 60 DP1 at 100mm thick and EI 120 DP1 at 150mm thick (see Fig. 3). LLENTAB AB also makes panels 300mm thick for projects in the Nordic countries where the current requirements for thermal insulating properties of perimeter casing are currently more stringent.

[fusion_slider hover_type=”none” width=”” height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][fusion_slide type=”image” link=”” linktarget=”_self” lightbox=”no” /][/fusion_slider]

Roof cladding – type 2SF/2LF – double layer composite roof. The upper layer above the truss girder is made of trapezoid sheet roofing fitted with a layer preventing the dripping of condensed vapour. The structural elements are purlins set perpendicularly on the truss girder structures. The bottom layer under the truss girder structure forms the soffit in the hall. The supporting elements are Z-profiles suspended from the bottom girder flanges. Thermal insulation is inserted or blown between the profiles. Trapezoidal sheets make up the soffit layer.

[fusion_slider hover_type=”none” width=”” height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][fusion_slide type=”image” link=”” linktarget=”_self” lightbox=”no” /][/fusion_slider]

Type 4F wall cladding – the outer face of the wall cladding is made of trapezoidal sheets anchored through horizontally laid wall purlins to the supporting pillars of the hall. Thermal insulation is inserted between the wall purlins. Trapezoidal sheets make up the interior visible layer.

[fusion_slider hover_type=”none” width=”” height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][fusion_slide type=”image” link=”” linktarget=”_self” lightbox=”no” /][/fusion_slider]

Type 7 wall cladding – the outer face of the wall cladding is made of sandwich panels with PUR, PIR or mineral wool insulating core. The panels are laid horizontally and anchored to the hall pillars.